Dust Collector System: You need a durable rotary valve to keep production going strong.

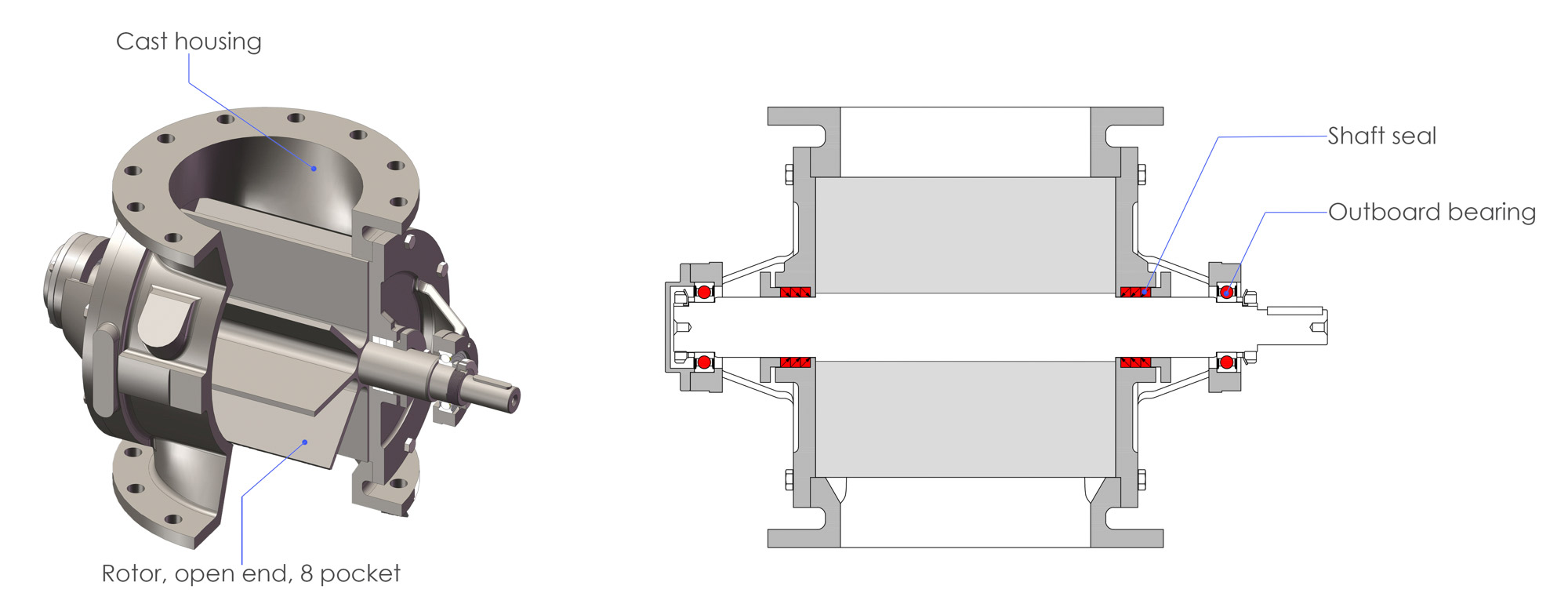

Structure of Medium duty rotary valve

Features and Function

| Options

| ||

| • | Available in 10 flange diameters from 100mm to 600mm; and 10 heights, from 190mm to 930mm | • | 6 vane, 10 vane or 12 vane rotor. |

| • | Standard Valves manufactured in cast iron. | • | Rotor design: close ended, and adjustable-tip |

| • | Drilled flanges in accordance with GB PN10, ANSI 150#, DIN PN10, JIS10K | • | Interior coatings: hard chrome, tungsten, and Teflon |

| • | Close vane tolerances ensure high sealing and feeding efficiency and minimum air leakage. | • | Replaceable rotor wear tips |

| • | Outboard bearings are standard and a full range of shaft seal options is available | • | Interior coatings: hard chrome, tungsten, and Teflon |

| • | Excellent performance in high-temperature applications up to 250°C. | • | Air purge shaft sealing |

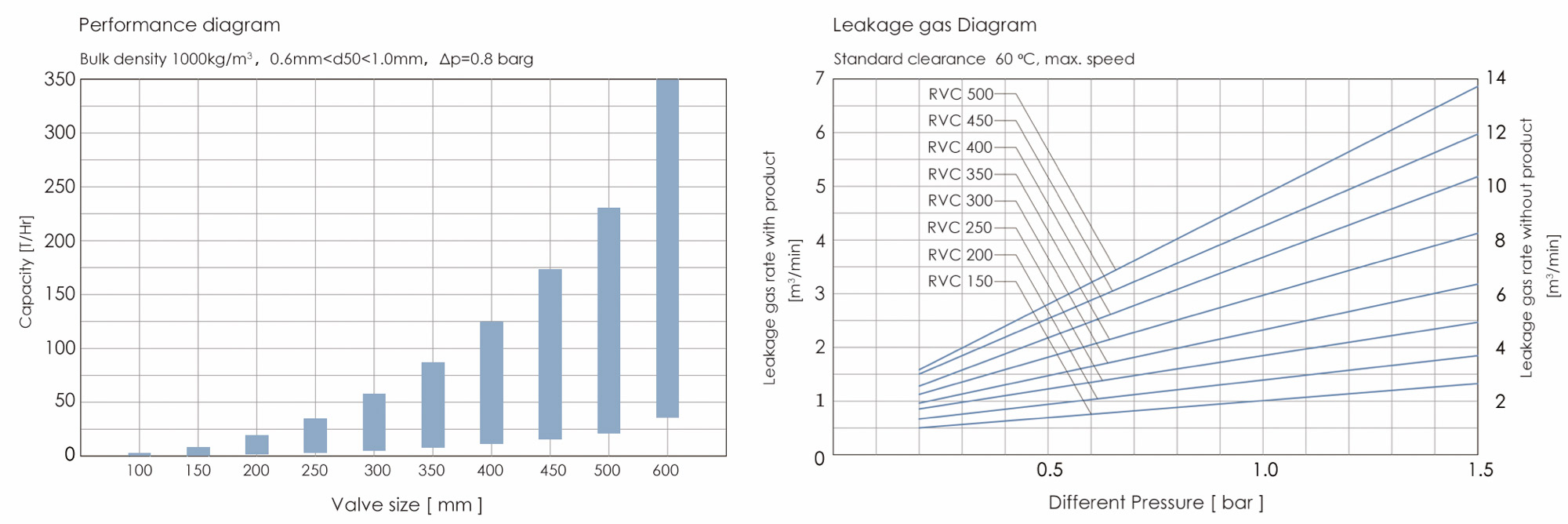

| • | Pressure differentials up to 1.5bar (21PSI). | • | Valve housing vent ports. |

| • | Open ended rotor with 8 vans | • | Accessories: Drop-out box, speed monitor, vent box, Air purge regulation station. |

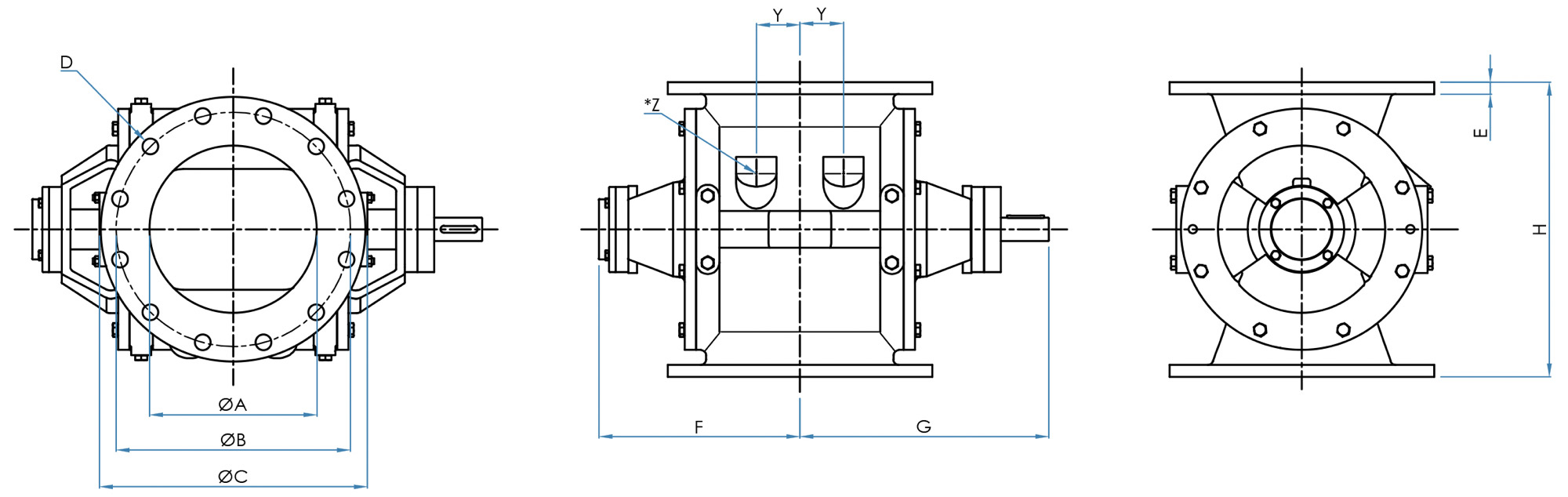

Dimensions of RVC

Volumetric Capacity

Model | Ltr/Rev | Inlet*/Outlet | Other Dimensions | |||||||||||

Ø A | Ø B DIN | Ø C DIN | D DIN | Ø B ANSI | Ø C ANSI | D ANSI | E | H | F | G | Y | *Z | ||

RVC 100 | 1 | 100 | 180 | 220 | 8 x Ø 18 | —— | —— | —— | 10 | 190 | 180 | 240 | —— | —— |

RVC 150 | 4 | 150 | 240 | 285 | 8 x Ø 22 | 241.3 | 279 | 8 x Ø 22.2 | 15 | 320 | 225 | 275 | 37.5 | 1" |

RVC 200 | 10 | 200 | 295 | 340 | 8 x Ø 22 | 298.4 | 343 | 8 x Ø 22.2 | 15 | 380 | 255 | 315 | 55 | 1¼" |

RVC 250 | 18 | 250 | 350 | 395 | 8 x Ø 22 | 361.9 | 406 | 8 x Ø 25.4 | 18 | 440 | 300 | 370 | 65 | 1¼" |

RVC 300 | 30 | 300 | 400 | 445 | 8 x Ø 22 | 431.8 | 483 | 8 x Ø 25.4 | 23 | 520 | 340 | 420 | 85 | 1¼" |

RVC 350 | 45 | 350 | 460 | 505 | 8 x Ø 22 | 476.2 | 533 | 8 x Ø 28.6 | 25 | 580 | 378 | 460 | 90 | 1½" |

RVC 400 | 65 | 400 | 515 | 565 | 8 x Ø 24 | 539.7 | 597 | 8 x Ø 28.6 | 25 | 640 | 408 | 490 | 105 | 1½" |

RVC 450 | 90 | 450 | 565 | 615 | 8 x Ø 24 | 577.8 | 635 | 8 x Ø 31.7 | 25 | 700 | 445 | 550 | 115 | 1½" |

RVC 500 | 120 | 500 | 620 | 670 | 8 x Ø 24 | 635 | 699 | 8 x Ø 31.7 | 30 | 780 | 480 | 595 | 130 | 2" |

RVC 600 | 200 | 600 | 725 | 780 | 8 x Ø30 | 749.3 | 813 | 8 x Ø 34.9 | 35 | 930 | 550 | 660 | 190 | 2" |

*Note: Technical modification are possiblem dimensions in mm | ||||||||||||||

Product Introduction

- No.7, Jinqiu Road, Qinxiang Village, Lijia Town, Wujin District, Changzhou City

- 0086-18015812727

- info@jncvalve.com