What options can help sticky material flow better?

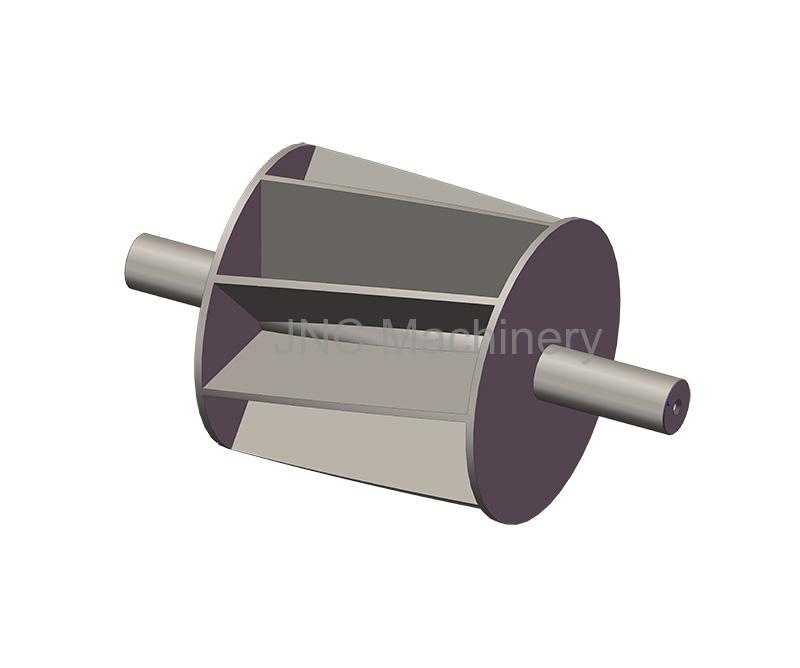

1. Rotor design

Open rotor – Fewer surfaces for the sticky material to cling to.

Rotor with scrapers – Wiper blades scrape the housing bore clean on each rotation.

Reduced pocket depth – Shallower pockets so material doesn’t compact and stick.

2. Surface treatment & material choice

Polished stainless steel (mirror finish) – Smooth surfaces make sticking harder.

Non-stick coatings – PTFE, hard anodizing, or ceramic coatings reduce adhesion.

Nitrided or chrome-plated surfaces – Improve smoothness and hardness.

3. Housing & clearances

Slightly increased rotor-to-housing clearance – Prevents jamming when material builds up (but may increase leakage).

Self-cleaning housing geometry – Avoids dead zones where material can cake.

4. Air assist

Purge air in the rotor pockets – Blows material out before it can stick.

Housing purge air (air knife) – Creates a barrier that reduces buildup on critical surfaces.

5. Heating or cooling

Heating jacket – Keeps temperature above the material’s tacky point.

Cooling jacket – For materials that get sticky when warm, lowering temperature can help.

6. Operational adjustments

Slower rotor speed – Gives material more time to discharge without smearing.

Avoid overfilling pockets – Reduces compaction that worsens sticking.

Intermittent cleaning cycles – Flush with air or small cleaning batches.

7. Upstream/downstream aids

Vibratory feeder or agitator above the valve – Keeps material loose before it enters.

Discharge assistance – Pneumatic conveying suction immediately below the valve can help pull material out.

- No.7, Jinqiu Road, Qinxiang Village, Lijia Town, Wujin District, Changzhou City

- 0086-18015812727

- info@jncvalve.com