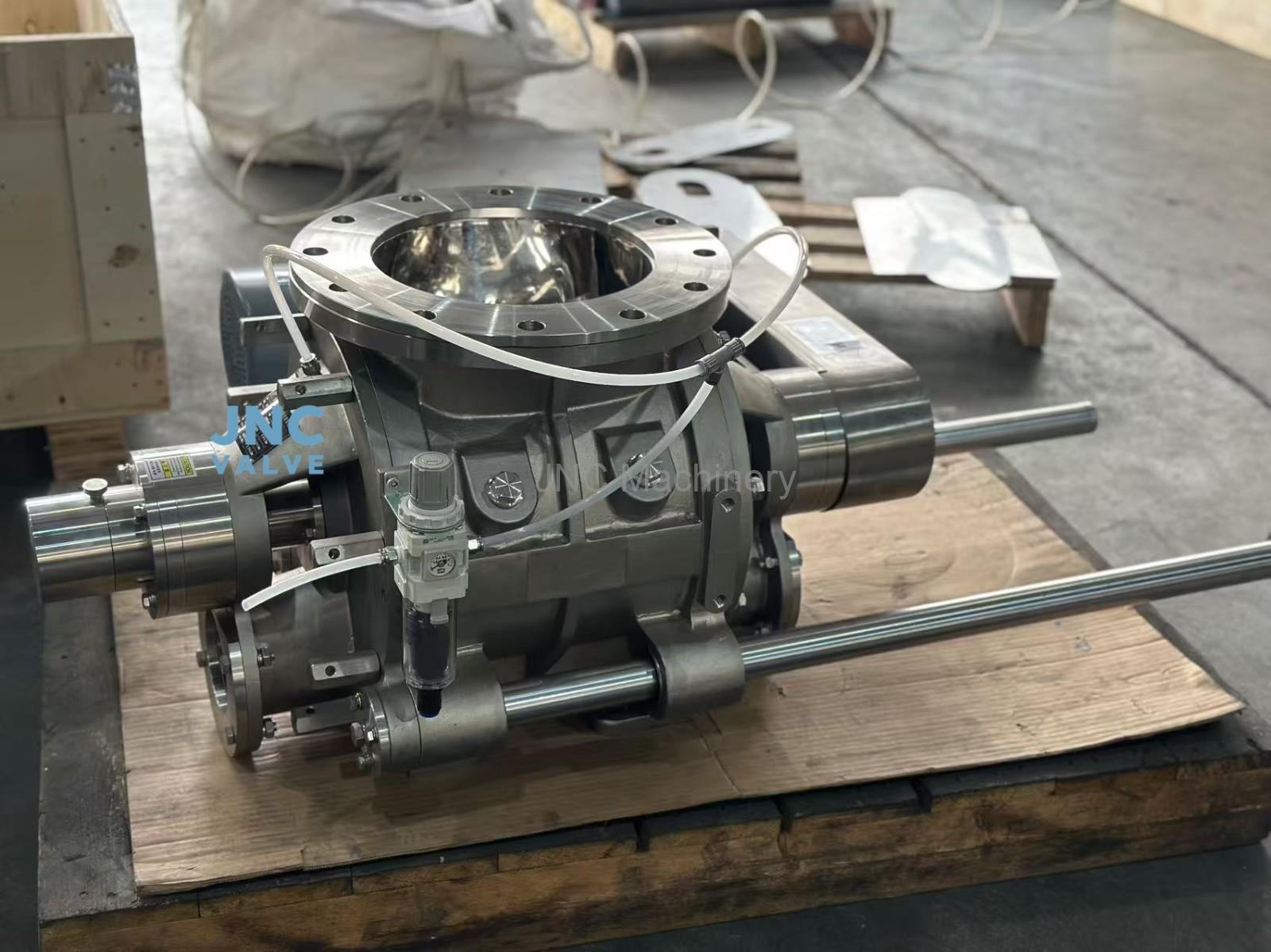

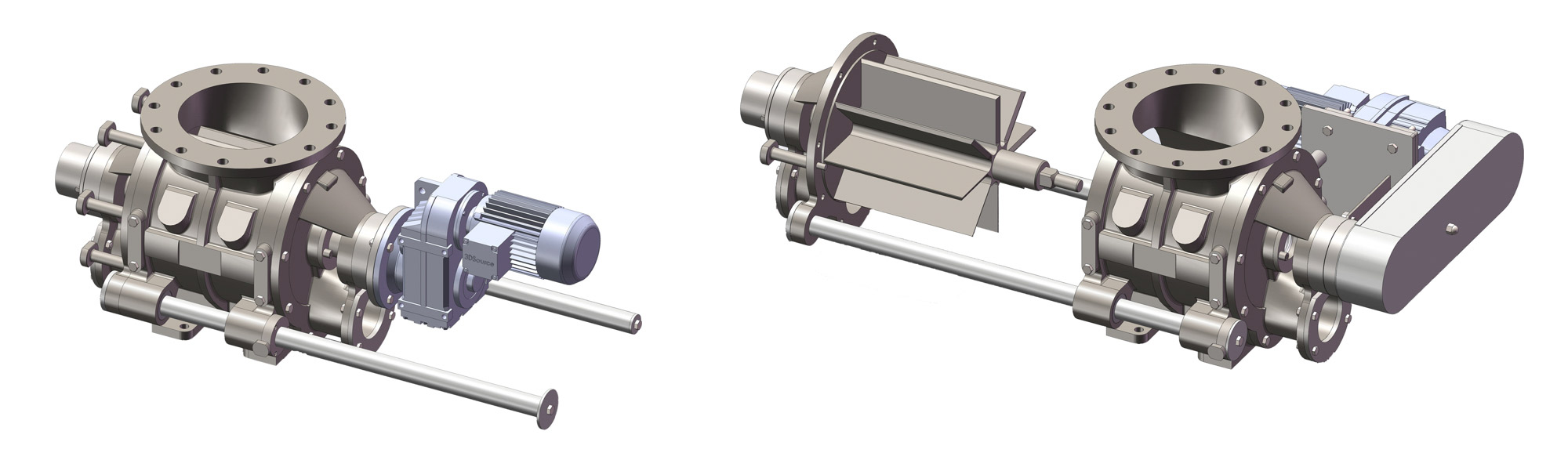

Powder Handling Solution: A rail system makes it much easier to clean the rotor, perform maintenance or repairs, adjust the rotor tips, and inspect the valve's internals.

Structure of blow through rotary valve RBQ

Features and Function

| Options

| ||

• | Available in 4 flange diameters from 150mm to 300mm; | • | 304, 316,304L,316L cast stainless steel valve housing |

• | Standard Valves manufactured in Stainless Steel 304 | • | 10 vane or 12 vane rotor. |

• | Heavy duty slide rail assembly | • | Rotor design: radius pocket and adjustable-tip |

• | Twin track linear bearing assembly | • | Replaceable rotor wear tips |

• | Drilled flanges in accordance with GB PN10, ANSI 150#, | • | Interior coatings: hard chrome, tungsten, and Teflon |

• | Close vane tolerances ensure high sealing and feeding | • | Air purge shaft sealing |

• | Outboard bearings are standard and a full range of | • | Valve housing vent ports. |

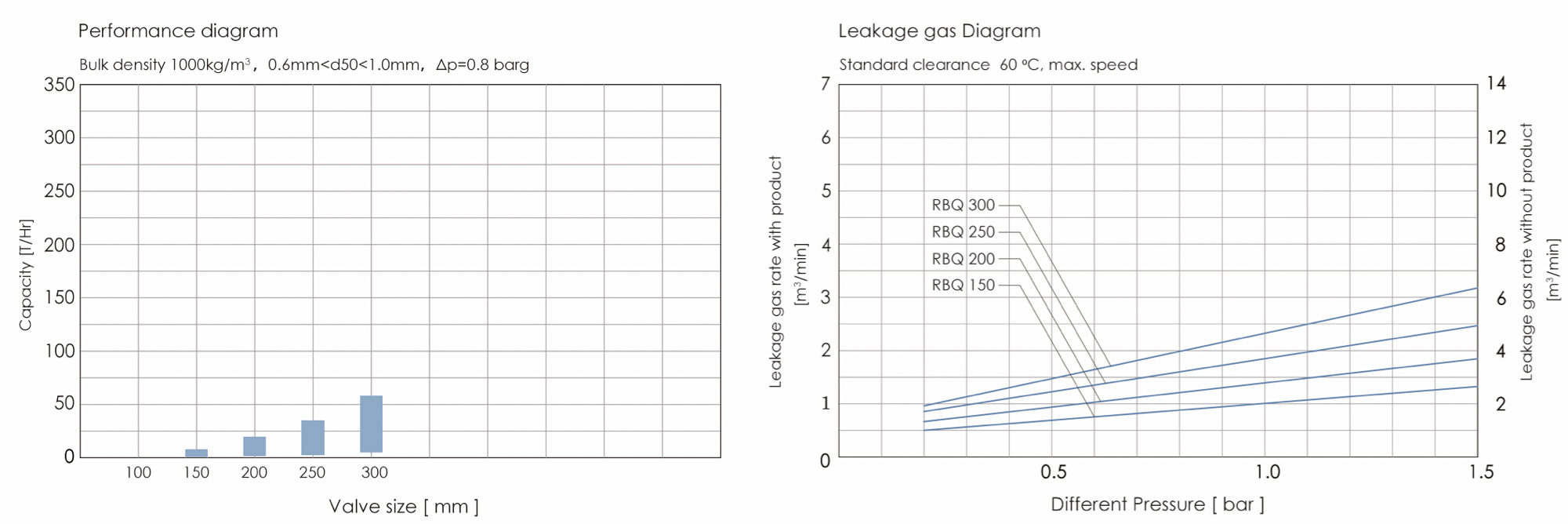

• | Pressure differentials up to 1.5bar (21PSI). | • | Accessories: Speed monitor, vent hopper, |

• | Open ended rotor with 8 vans | ||

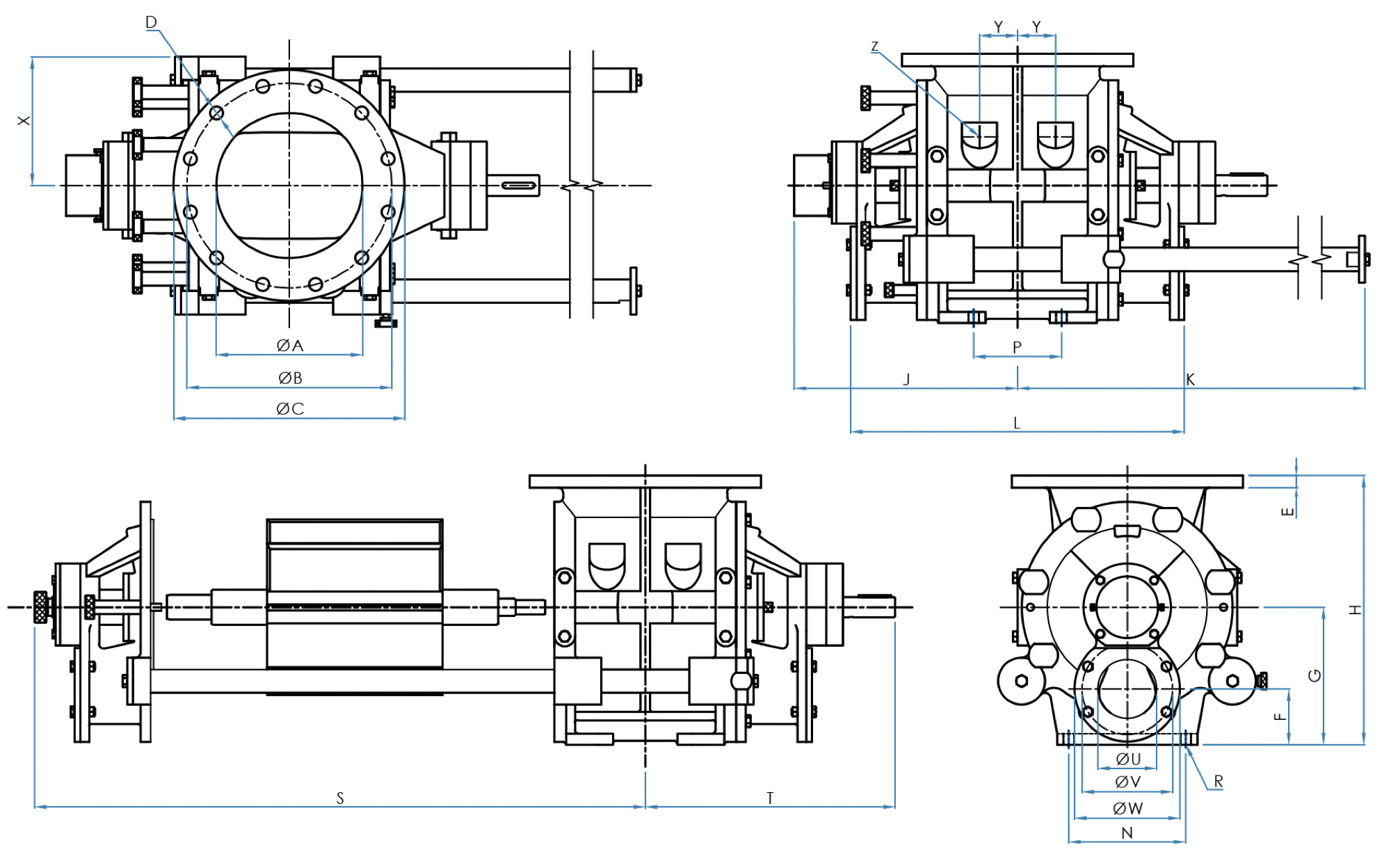

Dimensions of RBQ

Volumetric Capacity

Model | Ltr/Rev | Inlet* | Blow through channel | |||||||||||

Ø A | Ø B DIN | Ø C DIN | D DIN | Ø B ANSI | Ø C ANSI | D ANSI | Ø U | Ø V | Ø W | |||||

RBQ 150 | 4 | 150 | 240 | 285 | 8 x Ø 22 | 241.3 | 279 | 8 x Ø 22.2 | 65 | 100 | 130 | |||

RBQ 200 | 10 | 200 | 295 | 340 | 8 x Ø 22 | 298.4 | 343 | 8 x Ø 22.2 | 80 | 130 | 150 | |||

RBQ 250 | 18 | 250 | 350 | 395 | 8 x Ø 22 | 361.9 | 406 | 8 x Ø 25.4 | 100 | 155 | 180 | |||

RBQ 300 | 30 | 300 | 400 | 445 | 8 x Ø 22 | 431.8 | 483 | 8 x Ø 25.4 | 125 | 180 | 210 | |||

Model | Other Dimensions | ||||||||||||||

E | F | G | H | J | K | L | N | P | R | S | T | X | Y | *Z | |

RBQ 150 | 18 | 70 | 170 | 340 | 300 | 695 | 370 | 130 | 100 | 4 x Ø 16 | 885 | 320 | 152 | 37.5 | 1" |

RBQ 200 | 18 | 80 | 200 | 390 | 330 | 755 | 430 | 160 | 130 | 4 x Ø 16 | 945 | 350 | 187 | 55 | 1¼" |

RBQ 250 | 21 | 95 | 235 | 460 | 380 | 870 | 510 | 200 | 150 | 4 x Ø 18 | 1040 | 420 | 220 | 65 | 1¼" |

RBQ 300 | 25 | 110 | 270 | 530 | 435 | 945 | 590 | 240 | 180 | 4 x Ø 18 | 1180 | 465 | 259 | 85 | 1¼" |

*Note: Technical modification are possiblem dimensions in mm | |||||||||||||||

Product Introduction

- No.7, Jinqiu Road, Qinxiang Village, Lijia Town, Wujin District, Changzhou City

- 0086-18015812727

- info@jncvalve.com