My process involves caustic or acidic chemicals. Which rotary valve options are best to ensure a long lifespan and minimal risk of corrosion?

1. Material of Construction

a. Stainless Steel (SS316 or higher)

Why: Offers excellent resistance to most acids and caustic chemicals.

Best For: General chemical applications where corrosion is a risk.

Notes: SS316 is preferred over SS304 due to its higher molybdenum content, which improves resistance to chlorides and strong acids.

b. Polymer-Lined or Coated Valves

Why: Offer a protective barrier between the metal and chemicals.

Best For: Applications where exotic alloys are too costly, but corrosion resistance is still critical.

Notes: PTFE-lined valves are commonly used in pharmaceutical and chemical industries.

2. Sealing System

Chemical-resistant seals (like Viton, PTFE, or EPDM) are crucial to prevent leaks and seal degradation.

Avoid standard nitrile seals, which can degrade quickly in acidic or caustic environments.

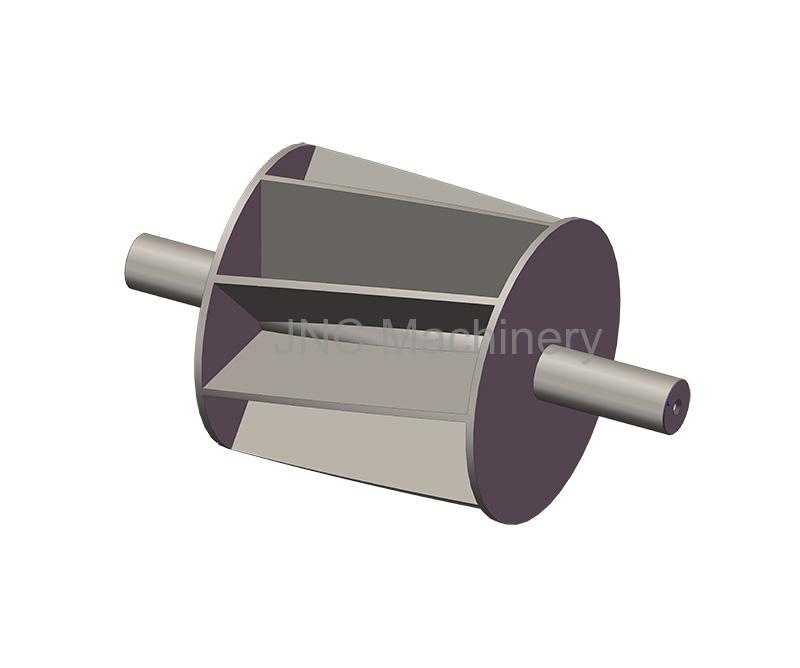

3. Rotor Design

Use closed-end rotors to reduce chemical ingress into the rotor shaft.

Consider coated or solid stainless-steel rotors for better durability.

4. Maintenance Features

Choose a quick-clean design if regular cleaning is required.

Ensure easy disassembly without compromising seal integrity.

Checklist Before Choosing:

1.What exact chemicals are involved?

2.What is the concentration and temperature of the media?

3.Is CIP (clean-in-place) or manual cleaning needed?

- No.7, Jinqiu Road, Qinxiang Village, Lijia Town, Wujin District, Changzhou City

- 0086-18015812727

- info@jncvalve.com