What Are the Different Types of Rotary Airlock Valves?

There are many types of rotary airlock valves — each tailored to specific materials, systems, and industries. At JNC Valves, our standard RVC/S Series is a popular choice thanks to its robust construction and wide range of customization options. But we offer dozens of other configurations based on:

1. Your Application

Whether you're in construction, pet food production, biomass handling, or cannabis processing, different industries demand different valve solutions.

2. Your Material

From fine powders like flour and cement to abrasive or sticky materials like plastic pellets or sugar, your valve should be designed for your material’s characteristics.

3. Your System Setup

Are you feeding a dust collector, a silo, or a pneumatic conveying line? System configuration influences valve selection, sizing, and features.

4. Your Process Needs

Do you need an airlock with metering? A pure feeding valve? Or both? Understanding the function your valve needs to perform is key.

5. You can go even further by customizing valves with:

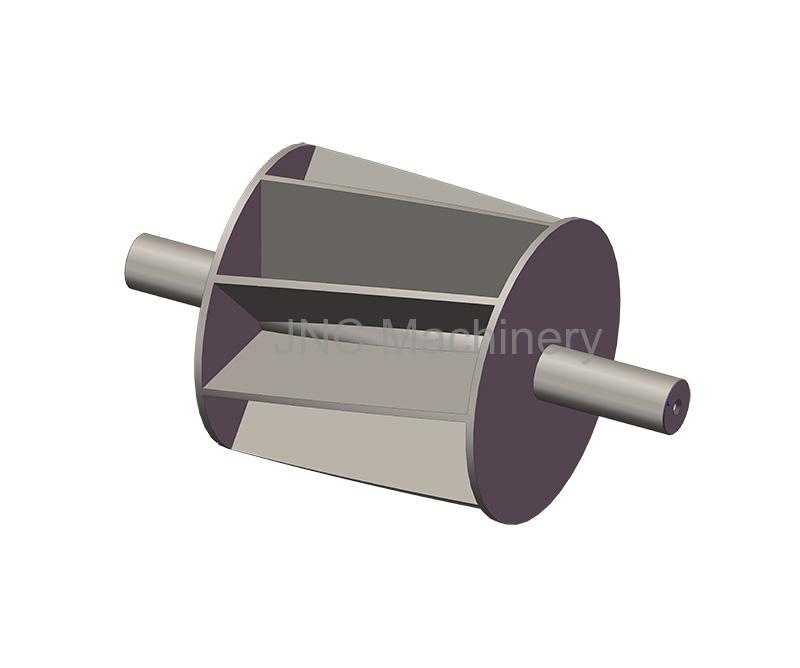

1.Special rotors (U-shaped, scalloped, closed-end, etc.)

2.Wear-resistant or food-grade coatings

3.Air purge shafts, easy-clean rails, or explosion vents

▲ Need help choosing?

The easiest way to find the right valve is to speak with a JNC Valves sale. We'll recommend exactly what your process requires — no more, no less.

- No.7, Jinqiu Road, Qinxiang Village, Lijia Town, Wujin District, Changzhou City

- 0086-18015812727

- info@jncvalve.com