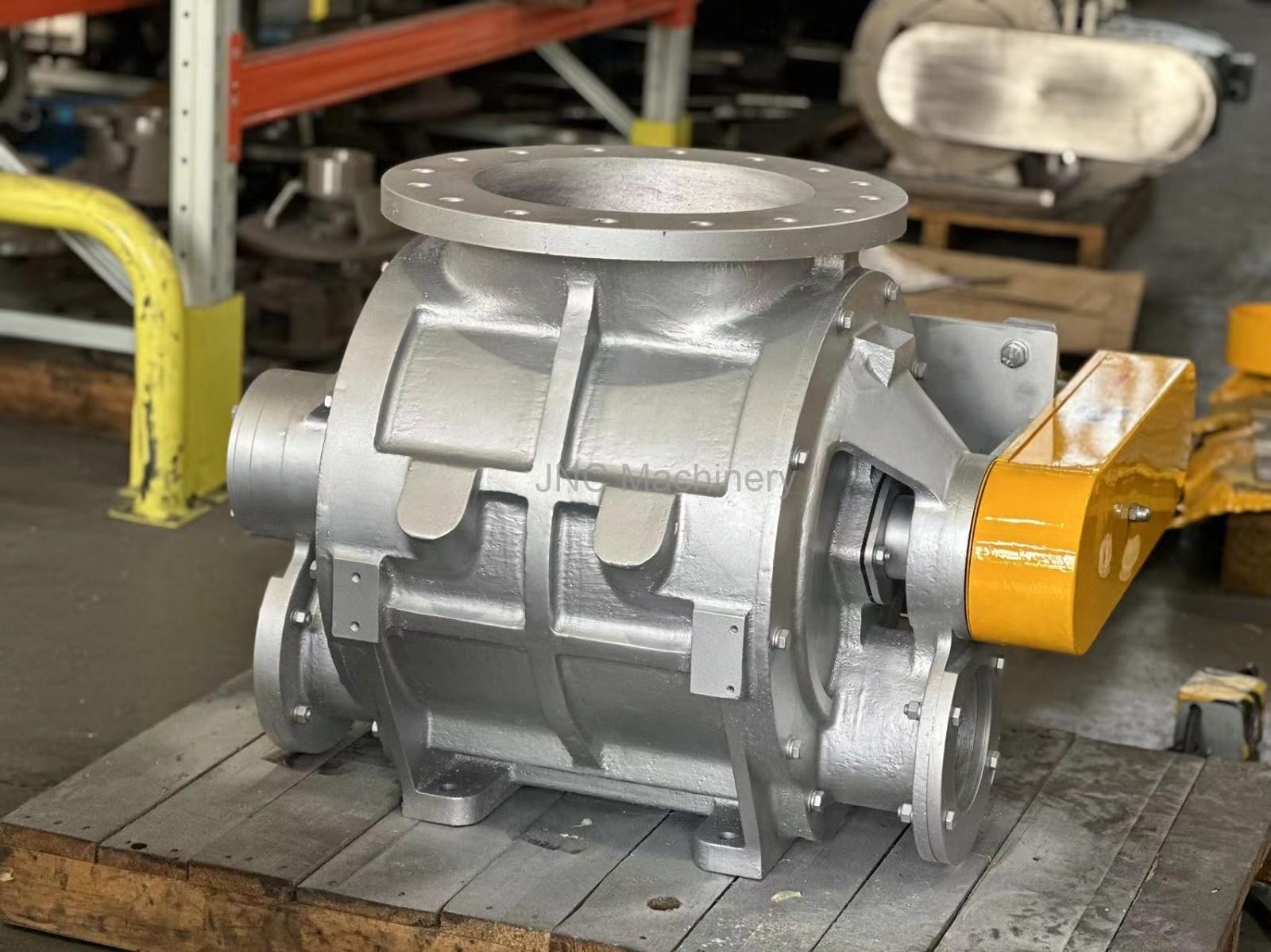

Dust Collector System: You need a durable rotary valve to keep production going strong.

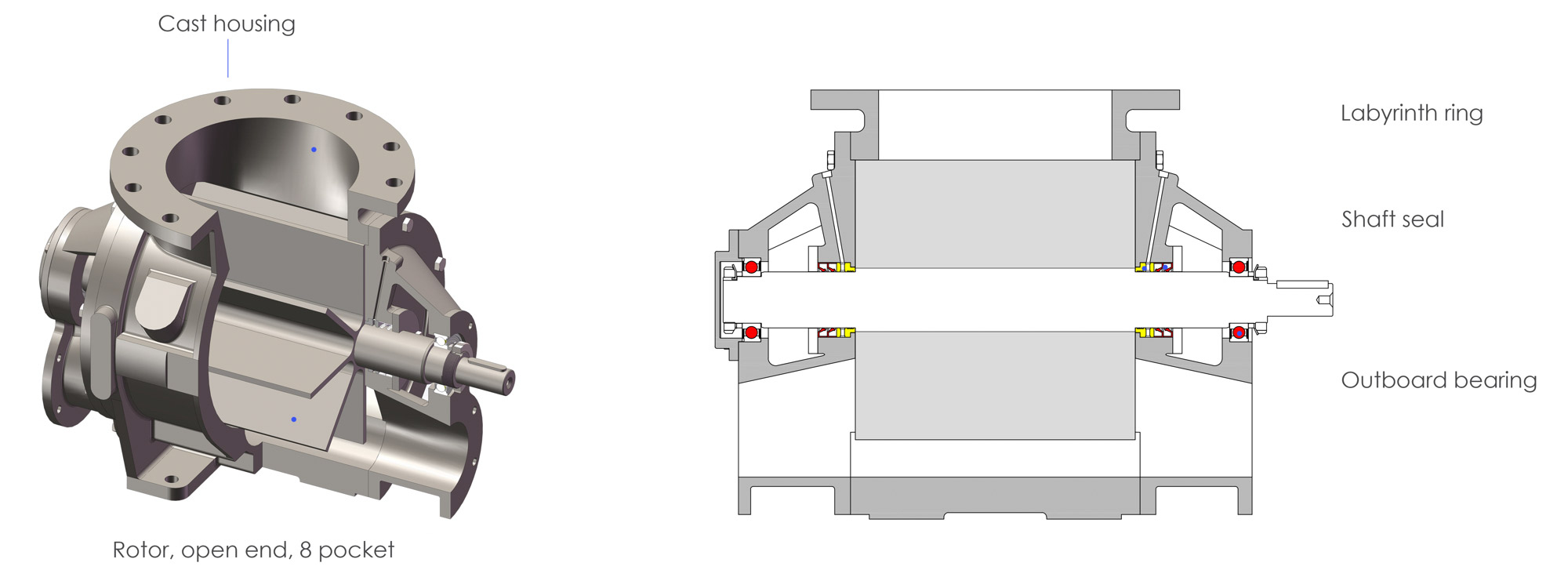

Structure of blow-thru rotary valve

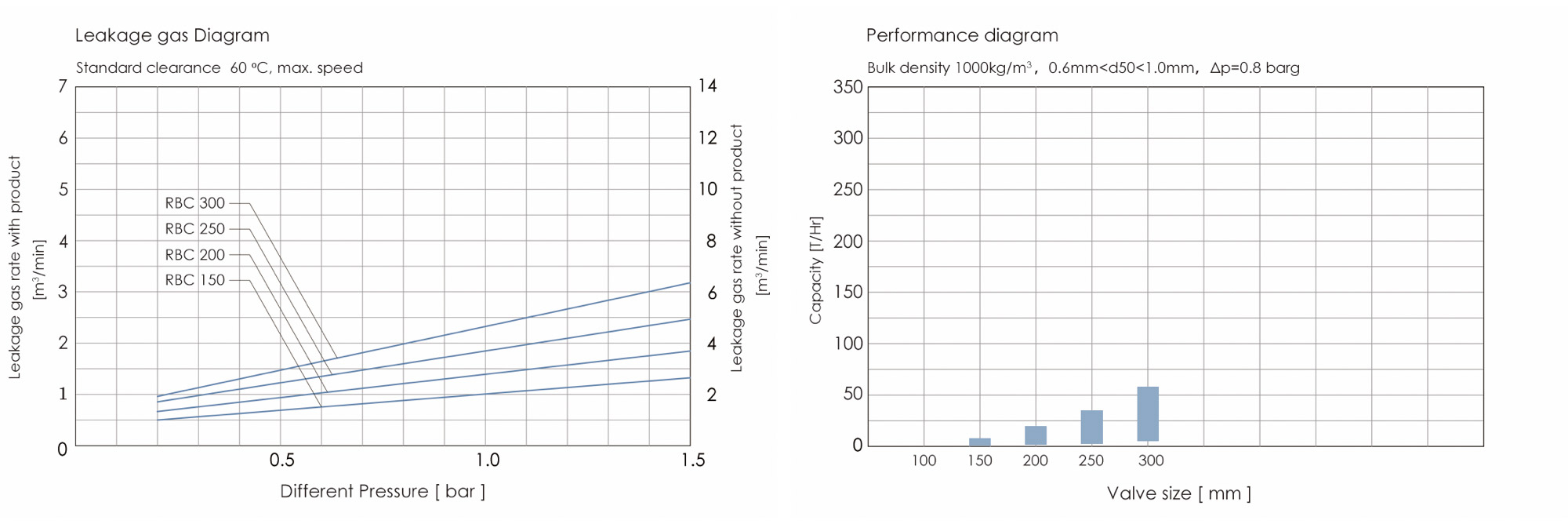

Features and Function

| Options | ||

| • | Available in 4 flange dimensions from 150mm to 300mm; | • | Open ended rotor with 8 vans |

| • | Standard Valves manufactured in cast iron | • | Rotor design: radius pocket, and adjustable-tip |

| • | Drilled flanges in accordance with GB PN10, ANSI 150#, DIN PN10, JIS10K | • | Replaceable rotor wear tips |

| • | Close vane tolerances ensure high sealing and feeding efficiency and minimum air leakage. | • | Interior coatings: hard chrome, tungsten, and Teflon |

| • | Outboard bearings are standard and a full range of shaft seal options is available | • | Air purge shaft sealing |

| • | Excellent performance in high-temperature applications up to 250°C | • | Valve housing vent ports. |

| • | Pressure differentials up to 1.5bar (21PSI). | • | Accessories: Speed monitor, vent hopper, Air purge regulation station. |

| • | Open ended rotor with 8 vans | • | Accessories: Drop-out box, speed monitor, vent box, Air purge regulation station. |

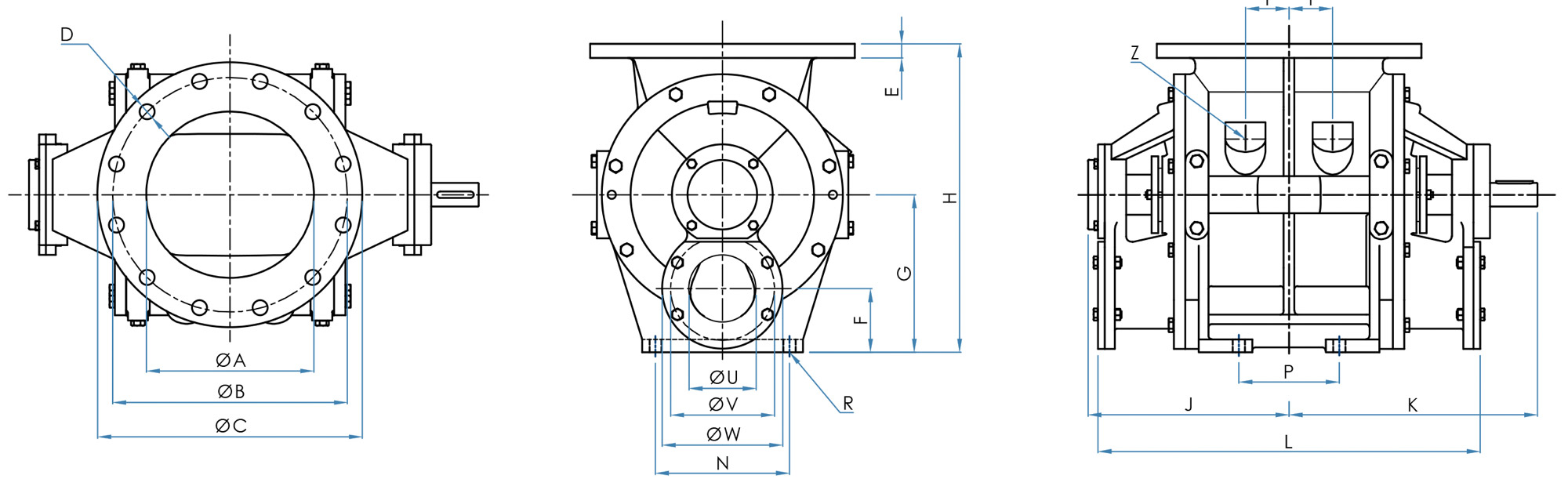

Dimensions of RBC

Volumetric Capacity

Model | Ltr/Rev | Inlet* | Blow through channel | |||||||||||

Ø A | Ø B DIN | Ø C DIN | D DIN | Ø B ANSI | Ø C ANSI | D ANSI | Ø U | Ø V | Ø W | |||||

RBC 150 | 4 | 150 | 240 | 285 | 8 x Ø 22 | 241.3 | 279 | 8 x Ø 22.2 | 65 | 100 | 130 | |||

RBC 200 | 10 | 200 | 295 | 340 | 8 x Ø 22 | 298.4 | 343 | 8 x Ø 22.2 | 80 | 130 | 150 | |||

RBC 250 | 18 | 250 | 350 | 395 | 8 x Ø 22 | 361.9 | 406 | 8 x Ø 25.4 | 100 | 155 | 180 | |||

RBC 300 | 30 | 300 | 400 | 445 | 8 x Ø 22 | 431.8 | 483 | 8 x Ø 25.4 | 125 | 180 | 210 | |||

Model | Other Dimensions | |||||||||||

E | F | G | H | J | K | L | N | P | R | Y | *Z | |

RBC 150 | 18 | 70 | 170 | 340 | 225 | 275 | 370 | 130 | 100 | 4 x Ø 16 | 37.5 | 1" |

RBC 200 | 18 | 80 | 200 | 390 | 255 | 315 | 430 | 160 | 130 | 4 x Ø 16 | 55 | 1¼" |

RBC 250 | 21 | 95 | 235 | 460 | 300 | 370 | 510 | 200 | 150 | 4 x Ø 18 | 65 | 1¼" |

RBC 300 | 25 | 110 | 270 | 530 | 340 | 420 | 590 | 240 | 180 | 4 x Ø 18 | 85 | 1¼" |

*Note: Technical modification are possiblem dimensions in mm | ||||||||||||

Product Introduction

- No.7, Jinqiu Road, Qinxiang Village, Lijia Town, Wujin District, Changzhou City

- 0086-18015812727

- info@jncvalve.com